Belt Skirting

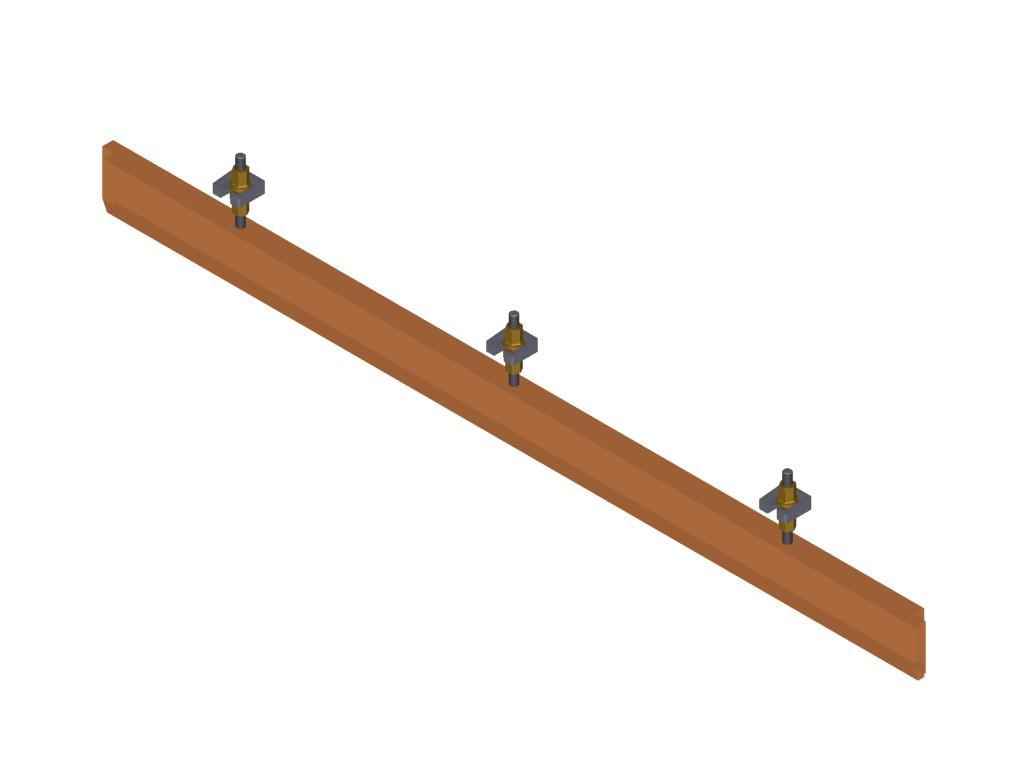

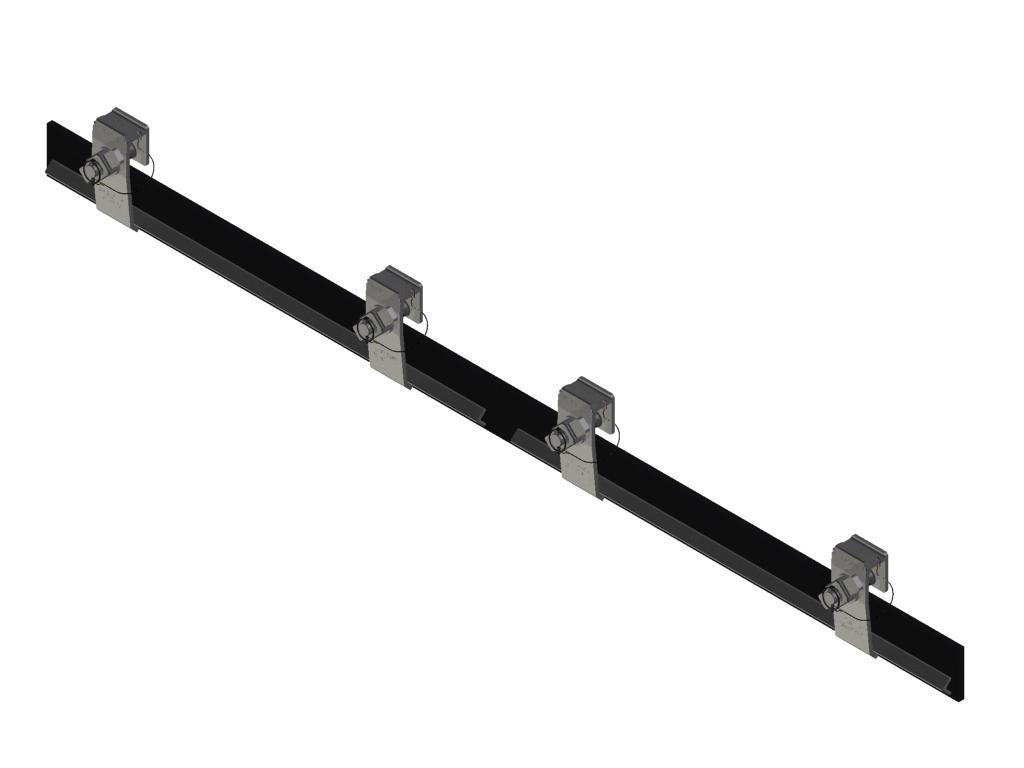

It is best practice to install a conveyor skirt system at any transfer point where product is being loaded from one conveyor to another. An effective skirt system comprises of a steel skirt plate, wear liner and dust sealing mechanism. The steel skirt plate is designed to mount the wear liner and sealing mechanism. The wear liner is designed to control and direct active product through transition until it settles in the trough of the outgoing conveyor belt. The sealing mechanisms only fuction is to retain dust within the transfer point.

The range of Yaga Engineering skirt systems has been designed to allow them to be fitted to new transfer points at the design/manufacture phase or retro-fitted, in-situ on existing conveyors.

In addition to supplying the skirt system Yaga Engineering can provide 30 metre rolls of either skirt rubber or polyurethane in various widths and thicknesses to suit your requirements.